Textile constructions

In the area of textile construction we are speaking about PVC-coated fabrics for halls, tents and

the textile architecture segment.

Application Description

Single layer systems for halls and tents

These systems are PVC-coated fabrics used to make premium tarpaulins for outdoor purposes. Because these tarpaulins are in use for long periods, the lacquer systems used must have an extraordinary profile of properties. ROWAFLON® PVDF lacquer systems provide exactly this. Developed to cater to this specific field, they have proven their worth time and time again in everyday use.

Their effective outdoor durability and UV resistance are beyond dispute. Further advantages of ROWAFLON®-protected flexible membranes include their low susceptibility to soiling, and their excellent cleaning characteristics.

Together with the plasticiser barrier effect, these positive characteristics ensure that ROWAFLON® lacquer systems are a first choice for textile construction.

2-layer systems for textile construction

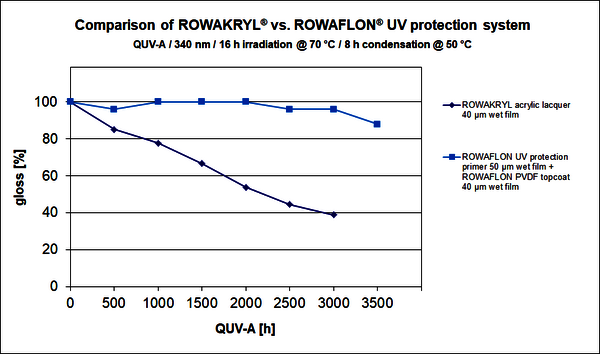

Textile construction is increasingly finding favour worldwide as a standard feature in contemporary architecture . ROWA Lack has now further developed the ROWAFLON ® lacquer systems product group. The development team's aim was to improve UV protection properties, thus extending the useful life of coated tarpaulin fabric substantially.

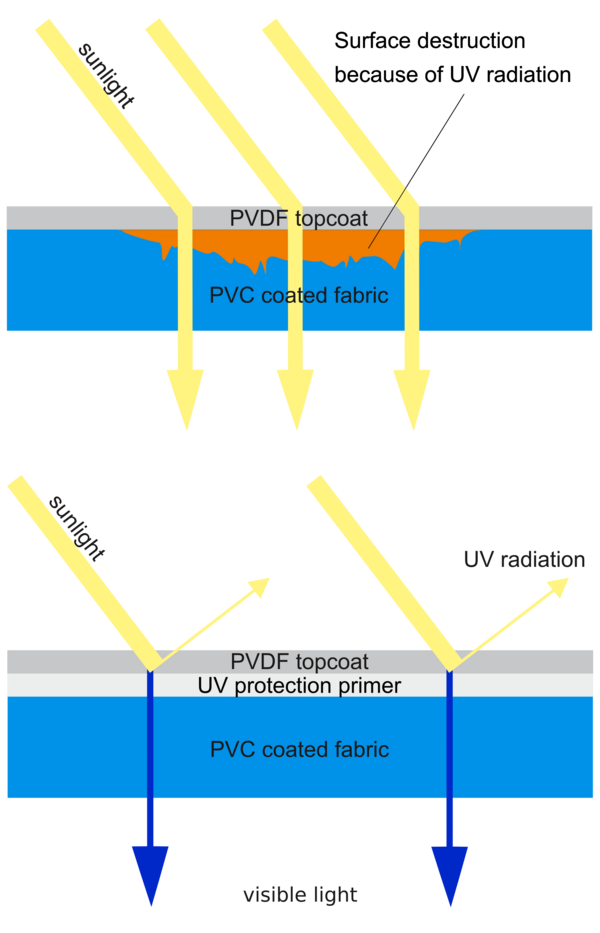

Exposure to intense UV irradiation will normally cause damage to the PVC boundary layer in tarpaulin fabric. This can impair the bond between the lacquer and the PVC surface, which, in turn, can have an adverse effect on the performance of the membranes, even if the lacquer film remains 100% intact.

The new UV protective primers, however, reflect or absorb any UV irradiation, thus protecting the sensitive PVC surface. Due to the high chemical resistance of the light protection agents used, their protective effect remains more or less constant over several years. The new systems can filter out more than 80% of the UV in sunlight, while transparency within the visible wavelength range is still above 70%.

Product Overview

| Product designation | ROWAFLON® G-75081W |

| Solids [%] | 19.5 |

| Solvents | Water, EDG |

| 1-Layer | X |

| 2-Layer | |

| Recommended applications / Properties | Halls and tents (waterborne) |

| Product designation | ROWAFLON® G-71711 |

| Solids [%] | 11.0 |

| Solvents | MEK, PMA |

| 1-Layer | X |

| 2-Layer | |

| Recommended applications / Properties | Halls and tents, textile constructions |

| Product designation | ROWAFLON® G-75277 |

| Solids [%] | 16.0 |

| Solvents | MEK |

| 1-Layer | X |

| 2-Layer | |

| Recommended applications / Properties | Halls and tents |

| Product designation | ROWAFLON® G-75372 |

| Solids [%] | 16.0 |

| Solvents | MEK, PMA, Acetone, Cyclohexanone |

| 1-Layer | X |

| 2-Layer | |

| Recommended applications / Properties | Halls and tents |

| Product designation | ROWAFLON® G-75368 |

| Solids [%] | 16.3 |

| Solvents | MEK, PMA, Cyclohexanone |

| 1-Layer | |

| 2-Layer | X |

| Recommended applications / Properties | Textile constructions, UV protection primer, TiO2 absorber |

| Product designation | ROWAFLON® G-75369 |

| Solids [%] | 16.3 |

| Solvents | MEK, PMA, Cyclohexanone |

| 1-Layer | |

| 2-Layer | X |

| Recommended applications / Properties | Textile constructions, UV protection primer, ZnO absorber |

| Product designation | ROWAFLON® G-75370 |

| Solids [%] | 16.3 |

| Solvents | MEK, PMA, Cyclohexanone |

| 1-Layer | |

| 2-Layer | X |

| Recommended applications / Properties | Textile constructions, UV protection primer, ZnO absorber (transparent) |

| Product designation | ROWAFLON® G-75281 |

| Solids [%] | 16.2 |

| Solvents | MEK, PMA |

| 1-Layer | |

| 2-Layer | X |

| Recommended applications / Properties | Textile constructions, topcoat for UV protection primer |

| Product designation | ROWAFLON® G-75428 |

| Solids [%] | 16.8 |

| Solvents | MEK, PMA, Cyclohexanone |

| 1-Layer | X |

| 2-Layer | X |

| Recommended applications / Properties | Halls and tents, textile constructions, topcoat for UV protection primer |

Additional information

As a result of continuous optimization and further development, the products shown in the tables are exclusively SVHC-free lacquer systems.

Our product recommendations and technical advice are based on careful investigation and are to our best knowledge but are without guarantee. Users have to test for themselves whether our products perform properly in their application.